Experience GE Vernova Hitachi Nuclear Energy’s award-winning VR training solutions—available at two US locations or set it up at your facility.

4x faster

than traditional methods

~82 million

Americans using VR

76%

more effective than

traditional methods

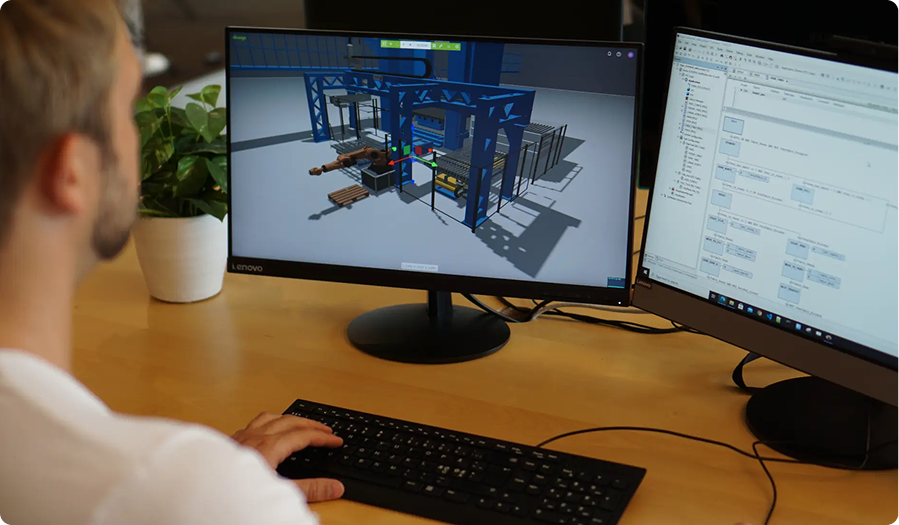

About nuclear VR training

GE Vernova Hitachi Nuclear Energy offers a unique, award-winning solution—based on Virtualware’s VIROO* platform and

immersive VR rooms concept—that allows personnel to simulate complex real-life nuclear power plant scenarios.

This system increases hands-on training time and prepares workers to handle unexpected events and emergencies with nuclear reactors.

Use GVH's nuclear VR training simulators at the following facilities:

GVH's nuclear services building—Wilmington, North Carolina

GVH's technology development center—San Jose, California

Your own facility—contact GE Vernova Hitachi Nuclear Services for more information

VR training benefits

Whether used on-site or remotely, VR simulation helps facilitate an easier, smoother, faster transition

to real world conditions with less equipment, fuel damage, and training delays.

unlimited repetitions

Increase hands-on training

with unlimited repetitions

infrequent situations training

Make infrequent situations

more frequent, and see how people react

combining abstract

and hands-on

Facilitate more learners—combining

both abstract and hands-on learners

Low-pressure environment

Low-pressure environment

where mistakes

carry

no real consequences

Better plant familiarity

Familiarization with

the power plant

through practice

Practice in a small space

Practice in a small space

whenever needed

Available simulators

Fuel movement simulator (FMS)

Helps facilitate fuel movement training within a plant-specific environment—Boiling Water Reactor (BWR). This nuclear plant simulator can be easily adapted to different plant/bridge designs.

By integrating a virtual reality immersive experience with the benefits of detailed training, the FMS offers a comprehensive and secure platform to configure training sessions. It replicates specific plant conditions, while also allowing the entire process to be monitored and training results to be preserved.

Vessel assembly and

vessel distension simulator

Helps facilitate vessel disassembly training within a plant-specific (BWR) environment via a physical tensioner replica connected directly to the virtual environment.

Trainees can perform vessel disassembly operations as they would in the real world. This nuclear reactor simulator monitors the entire disassembly process, detecting possible errors that operators may incur during the maneuver, while preserving training results for review at any time.

FMS, 2023 Brandon Hall

Gold Award Winner

GE Vernova Hitachi and Virtualware’s Fuel Movement Simulator (FMS) received a 2023 Best Advance in Augmented and Virtual Reality Gold medal award from the Brandon Hall Grou—known as the "Academy Awards of Human Capital Management."

Contact us

Experience the ultimate VR training solution — with GVH experts by your side